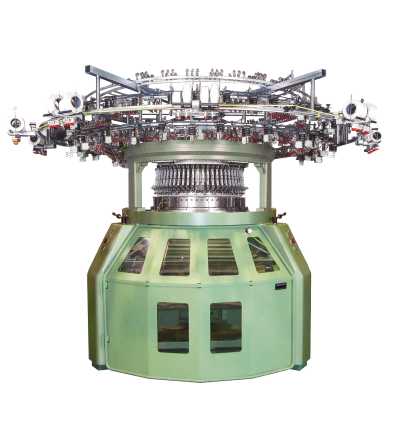

| Double knit multi-feeder machine with auto-stripers |

|

Newly designed high performance narrow-width F-type 3-colour auto-stripers

Highly productive thanks to the increased number of feeds and higher machine

speeds |

| |

| 【Main functions and features】 |

| <High performance and slim F-type 3-colour auto-stripers> |

・Suitable for double knit multi-feeder machines.

・The flip-up mechanism makes clear of the knitting head and this greatly

facilitates threading, fabric pressing-on, cleaning, etc.

・Random multi-finger operation where multiple fingers feed yarns at the

same time is possible. |

| |

| <Greatly improved productivity> |

・ The large number of feeds on double knit striper machines. (60 feeds

on 30")

・ Increased number of feeds and higher machine speeds allow greatly improved

productivity. |

| |

| <Stable operation at high speeds> |

・ Semi-closed cam system (stitch cam/raising cam separated type)

installed on the cylinder and dial ensures stable operation at high

speeds.

・ Exchange cam system for knit, tuck & welt on both the cylinder and

dial. |

| |

| <Cam timing can be changed by replacing cams> |

Delayed or synchronized timing can be selected by changing the cylinder

stitch cams.:

Cams for delayed and synchronized timing supplied as standard for 12G ~19G

machines (Rib specification) and Cams for delayed timing supplied as standard

for 20G~28G (Interlock specification). |

| |

| <Quick dial/cylinder change> |

| One day is enough for changing cylinder/dial thanks to the reduced numbers

of parts related to cylinder/dial change. |

| |

| <Easy and reliable elastomeric yarn feeding (optional)> |

| ・ Elastomeric yarns are supplied via guide rollers. There is no lint accumulation

in and around the elastomeric yarn paths. |

| |

| Fabric Samples(M-FY3) |

STRETCH 1X1 RIB |

STRAIGHT LINE INTERLOCK |

REVERSIBLE |

2X1 RIB |